In every project, every business wants every dollar, euro or pound to go further. This is why cost control in project management is a major concern – but it requires a more nuanced approach than merely budget slashing. Instead, costs should be optimised rather than controlled, per se. Cost optimisation isn’t just about cutting corners; it’s a strategic imperative that sharpens profitability and fuels sustainable growth, allowing businesses to outmanoeuvre competitors.

The role of a skilled Project Manager in this endeavour can’t be overstated. They provide valuable guidance on process improvements, coordination and cost optimisation steps. Over and above the discussion outlined here, I recommend hiring a Project Manager to ensure your initiative achieves maximum ROI.

However, to help potential clients better understand how an effective Project Manager plans, executes, and ensures ongoing cost optimisation within projects, I have outlined this comprehensive, organised, and focused framework. Ultimately, project success depends on proven techniques and the right tools; here, I provide insights into how a Project Manager deploys these principles.

Table of Contents

Defining terms in project management and budgeting

First, definitions. You may see the terms “cost control” and “cost optimisation” used interchangeably, but there are important nuances between the two practices. Cost control is primarily a reactive process focused on keeping actual costs within the planned budget. It involves monitoring expenses, identifying deviations, and taking corrective actions to prevent overspending. The main goal is to ensure adherence to the budget and maintain financial stability.

So, what is cost control in project management? Within this specific discipline, cost control refers to the processes used to monitor and manage a project’s budget. It ensures that actual expenses align with the approved plan. This includes forecasting potential cost overruns, tracking expenditures, and implementing corrective actions to keep the project within budget. Effective cost control helps to deliver the project without exceeding financial limitations.

So, if cost control refers to reactive measures to keep a project within budget, what is cost optimisation? Cost optimisation, on the other hand, is a more proactive and strategic approach. It’s a continuous process of finding and implementing ways to reduce expenses while maintaining or improving value and efficiency. Cost optimisation has a longer-term focus on maximising efficiency and return on investment.

Cost optimisation will be the focus of this discussion. Project Managers play a key role in this process, driving and coordinating cost optimisation efforts. Naturally, their primary goal is to boost efficiency and profitability in the long run.

An effective cost optimisation framework

Project definition and planning

Cost analysis in project management begins with thorough project definition and planning. This foundational step involves outlining objectives and establishing a clear framework for cost management throughout the project lifecycle. The first prerequisite is defining objectives.

Specific and measurable goals are essential. For example, you might aim for:

- Cost reduction of 15% within one year

- Increased efficiency through reduced throughput times by 20%

- Increased profitability

It is crucial to ensure that the goals align with the company’s strategy and its desired long-term growth. The goals to be set should be realistic but also challenging.

Furthermore, relevant stakeholders must be identified. Key personnel must be designated in the areas of finance, operations, IT, human resources and procurement. A clear definition of stakeholders facilitates better communication within the team, preventing misunderstandings and promoting seamless cooperation. This communication plan ensures stakeholders are informed and involved.

The next step is to assemble an interdisciplinary project team comprising internal experts and external consultants. For instance, many companies are currently investing heavily in AI projects; therefore, you may want to consider hiring AI Specialists. Alternatively, if your project focuses on strategy development, an external perspective from a Management Consultant could be extremely valuable. The Outvise platform is a great route to defining such profiles – if you’re at this stage, you can submit a free request now.

Interdisciplinary teams give the company a broader perspective and provide a framework for developing innovative ideas. It goes without saying that team roles should be clearly defined; this is the only way to ensure accountability and efficiency.

Analysis phase

Building upon the groundwork laid in project definition and planning, the subsequent critical step for Project Managers is the analysis phase. This process requires a thorough examination of several interrelated key areas. Many of these strategies originate in traditional approaches to cost control in project management, but with several important nuances.

Cost structure and efficiency

First, a comprehensive analysis of the cost structure is carried out. This identifies inefficient processes and bottlenecks, determining how total operating costs can be reduced through process optimisation and automation. Lean management principles are the go-to for such optimisations, as they aim to achieve a goal with the least effort possible. They focus on minimising waste, reducing costs, shortening processes and avoiding errors while optimising quality.

Alternatively, methods such as digital twin are suitable for testing processes virtually. Digital twins create a virtual representation of a product or system to help companies understand, predict and optimise the performance of a process. The representation is based on real-time data and makes it possible to visualise a process digitally. Based on this, weak points are identified.

Make or buy analysis

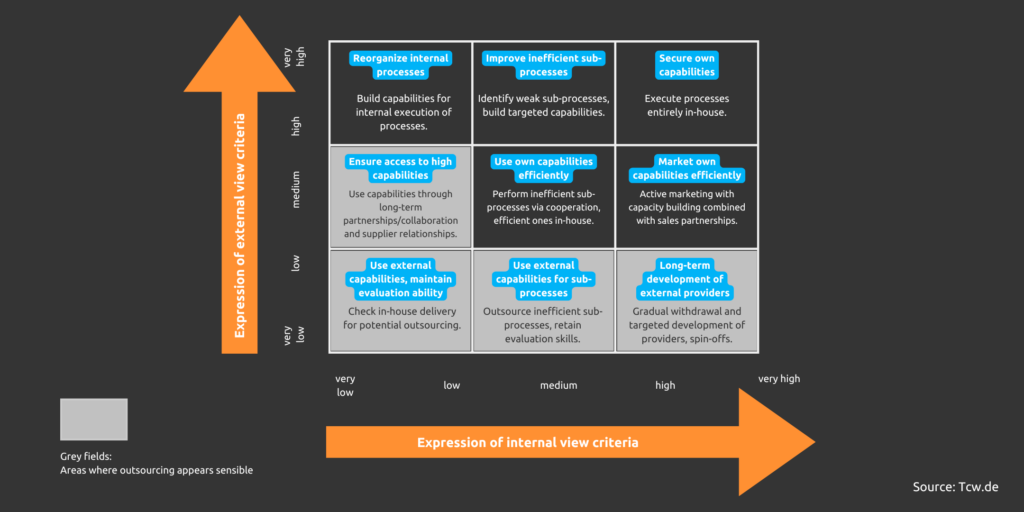

Next is an in-depth cost-benefit analysis, a process is also featured in traditional approaches to cost control in project management. In essence, this process facilitates decision-making by assessing whether certain products or services should be produced internally or sourced externally.

The total costs of in-house production are compared with the costs of procurement from external suppliers to select the most cost-effective option. Quality and time factors are among the key considerations, as well strategic considerations regarding outsourcing.

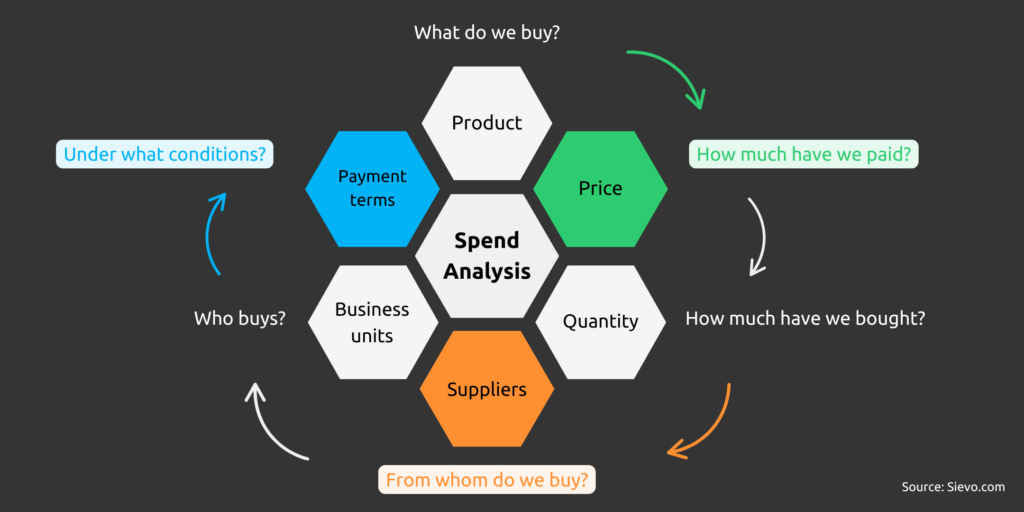

Procurement and supplier management

Following the make or buy analysis, existing relationships with suppliers are reviewed, along with the corresponding contractual terms and conditions. Based on the results, strategic decisions can be made regarding supplier changes or contract renegotiations. This enables the identification of potential savings, and a structured sourcing process can contribute to significant efficiency gains.

Personnel and resource management

Next comes another feature of more conventional approaches to cost control in project management: the Project Manager analyses personnel costs to identify excess capacity and potential optimisations. Shift models can be adjusted, and training courses can be held to increase efficiency and reduce costs. Resource planning and efficiency improvement tools can be used to support these measures. Leaving the traditional approaches and looking to the future, AI-supported tools are particularly useful in this area at present.

Ancillary costs and overheads

To plan savings effectively, it is essential to identify the main drivers of ancillary costs and overheads. For exmaple, operating costs can be reduced through energy-saving measures and by utilising more cost-effective suppliers. Ancillary costs should also be reviewed periodically once the project concludes.

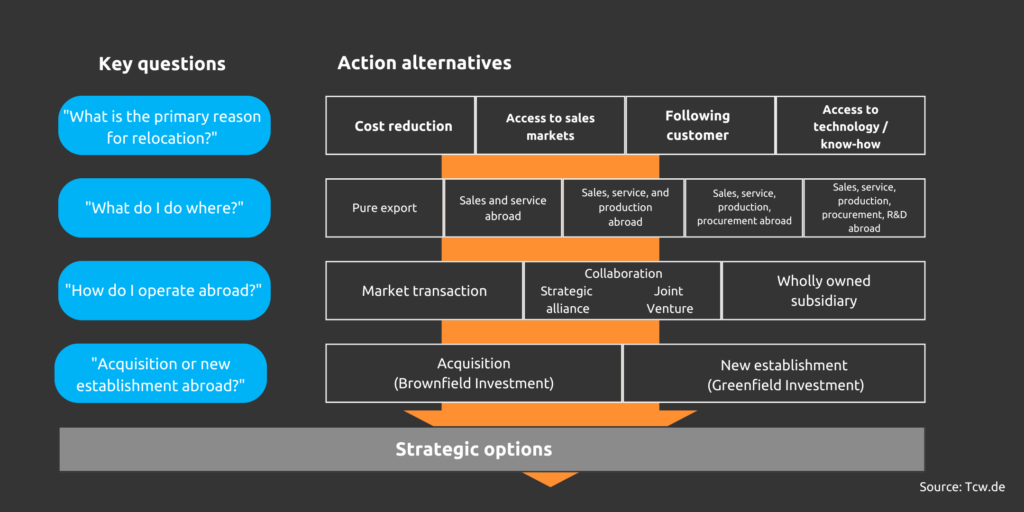

Relocation, especially nearshoring

In manufacturing contexts, an alternative geographic location may optimise operating costs and increase efficiency. Factors such as manufacturing costs, infrastructure and market proximity are taken into account when evaluating this aspect. The Project Manager will analyse potential cost reductions from site relocation, including labour cost reductions and logistics improvements.

They’ll also likely consider the possibility of nearshoring, which has become a popular approach as it often strikes a favourable balance between cost savings and geographical proximity.

For Germany, countries such as Poland, the Czech Republic, Hungary, Romania, and increasingly Serbia are options. Of course, an in-depth analysis of the countries in question is necessary. The advantage of this option over offshoring is the proximity to the target market, which is often not only a logistical advantage but also simplifies general management.

Waste and resource management

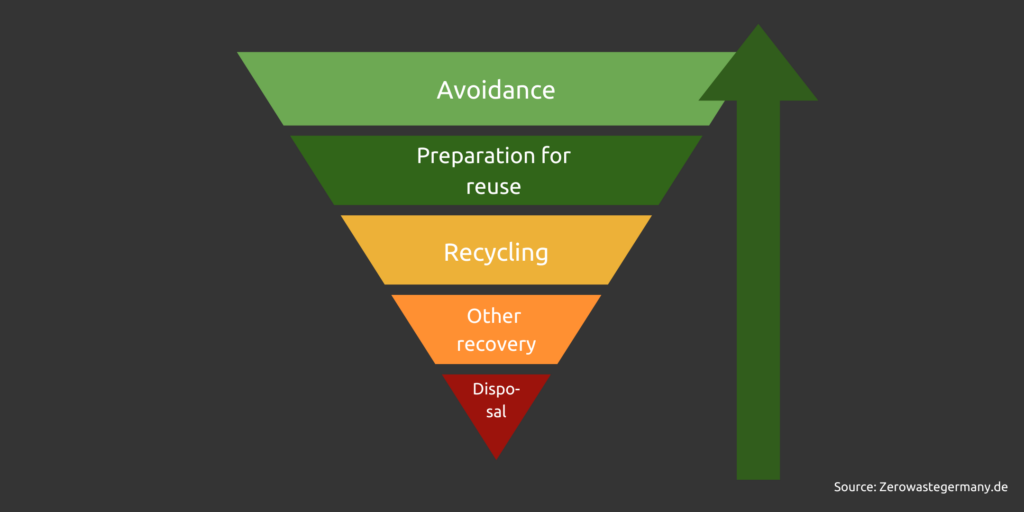

Now, we’ll turn away from these tried-and-tested approaches to cost control in project management to an area with optimisation truly at the core: waste and resource management. This phase focuses on developing sustainable strategies, which are increasingly integral to cost optimisation.

By minimising waste, companies not only reduce their environmental impact but also lower costs associated with material usage and disposal. Therefore, strategies for waste prevention and recycling, as well as broader sustainable practices, directly contribute to cost optimisation.

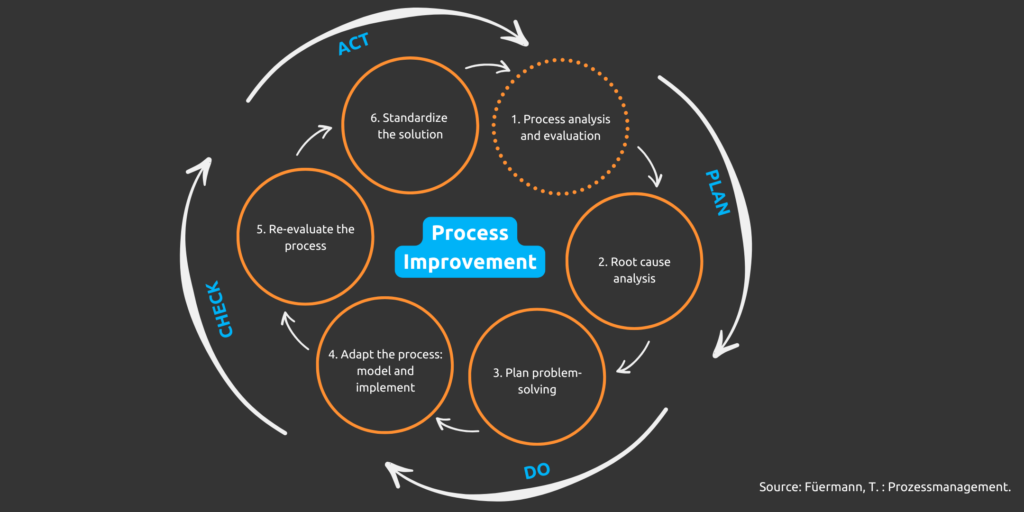

One method for achieving this improvement is the Six Sigma approach. This systematic five-phase model determines the relationship between cause and effect, enabling data-driven decisions for both sustainability and cost reduction. The five phases of the Six Sigma improvement process are also known as the DMAIC cycle: Define, Measure, Analyse, Improve, Control.

Six Sigma is notable for its method of viewing business processes as mathematical functions. In practical terms, this means:

- The problem and the desired outcome are clearly defined.

- The process steps causing the problem and their current performance are identified.

- The main reasons for the problem are thoroughly analysed.

- Solutions are developed and implemented.

- The improvements are sustained over time.

Identification and quantification of measures

Based on the analysis results, a list of feasible measures is compiled. This list can then be used to evaluate the individual measures in terms of their priority and potential savings. To improve planning, the savings are categorised and divided into short-term (the strategies you’ll likely recognise from conventional cost control in project management) and long-term savings (which are often more closely associated with optimisation over control).

Quantification, of course, refers to the representation of characteristics in mathematically measurable quantities. Facts and processes are converted into numerical values, which provide a concrete assessment of the financial impact on the income statement, balance sheet and cash flow.

Development of business cases

This quantification process lays the groundwork to create detailed business cases, which provide a comprehensive evaluation of each measure. A business case evaluates all the criteria of a project, including problem, solution, advantages and benefits, scope, stakeholders and resources, risks, costs and metrics for analysis.

A business case assesses whether a project or investment measure is worthwhile. Detailed business cases can be used to identify the ROI and other relevant factors. It is, of course, also essential to obtain approval from management and other relevant bodies.

Implementation phase

In the implementation phase, the approved measures are put into action. Applying change management principles is crucial to ensure effectiveness. This involves not only addressing individual problems but also making broad, targeted improvements to the company’s structures, processes, and behaviours.

Securing the necessary resources for successful implementation is a key consideration; for instance, the Project Manager might deploy tools such as Prosci ADKAR to help bring a clear structure to the change process. Other tools and frameworks include:

Program reporting

Regular reports are a crucial tool for teams and stakeholders to track the progress of implemented measures. A reporting system continuously compares current and planned savings to ensure accuracy.

Monitoring and control

The measures are continuously monitored through KPIs (key performance indicators). “Key” refers to key indicators that represent success and corporate goals; the effectiveness of the measures implemented and their impact on key company figures are measured. Dashboards for continuous monitoring of KPIs are particularly useful.

Evaluation and continuous improvement

The effectiveness of the measures implemented, their success and their financial impact are reviewed as part of the final stage of the process. Feedback loops are set up to gather experience that contributes to the continuous improvement of the programme, extending the impact of the cost optimisation exercise into the future.

Lessons learned

To optimise future initiatives, it’s essential to analyse the experience gained from completed projects, both during and after the implementation phase. Collecting and analysing this experience provides valuable knowledge that Project Managers can use when planning subsequent projects, leading to more effective strategies and implementation.

Train-the-trainer

To ensure the long-term success of cost optimisation efforts, developing internal expertise is crucial. A “train-the-trainer” programme can be implemented to this end. “Train-the-trainer” refers to training courses designed to equip employees to become trainers themselves. In the context of the cost optimisation post-programme, this approach aims to build the internal expertise and independence of employees.

Employees with high potential from various departments are selected to participate in a comprehensive training course on cost optimisation tools and methods. Participants also develop communication and leadership skills through practical workshops, along with the creation of a best practices guide. The training programme uses standardised training materials and digital resources and concludes with a train-the-trainer certification.

Executing effective cost optimisation in project management

Cost control in project management is an evolving field. As we move beyond control to optimisation, we recognise it as a continuous process with the overarching goal of increasing the profitability of the company. Cost optimisation leaves myopic view points at the door, recognising it can even be advantageous to make investments to reduce costs at a later stage.

In sum, cost optimisation is more than a series of isolated actions; it’s a strategic and ongoing commitment to maximising value. Project Managers are essential in driving this process, from the initial planning and analysis to the continuous evaluation and improvement of cost-saving measures. Their holistic perspective, analytical skills and leadership ensure that cost optimisation is integrated into every project phase.

To truly unlock the potential for sustainable cost reduction and enhanced profitability, businesses should secure the expertise of a skilled Project Manager. Outvise can help you identify an expert from your field, local to you.

Christian is a driven international professional with over 25 years of experience, offering a strong track record in delivering solutions and closing deals across finance, strategy, and mergers & acquisitions. With deep expertise in managing complex programs, he specializes in telecoms, tech, and other sectors like retail. Christian excels in leading business transformations and integrating digital and AI solutions. As a mentor, he also supports start-ups and scale-ups, helping them secure funding and successfully grow their market presence in today’s competitive landscape.

No comments yet

There are no comments on this post yet.